The Breitspurbahn: Adolf Hitler’s Train of Dreams: Part 1 – 3

Cover image courtesy of weaponsdandwarfare.com

The Breitspurbahn: Adolf Hitler’s Train of Dreams

Part 1. History

What is the Breitspurbahn? The Breitspurbahn was an idea postulated by Fritz Todt and Adolf Hitler that involved building a massive rail network across Europe, and ultimately across the Eurasian landmass, that would run on train tracks which were either 3 or 4 meters across. So, what we are talking about here is a massive network of trains that would be around twice the size of any conventional railways in use today. The whole Breitspurbahn project would have been totally forgotten by history if a German author, train engineer, and historical researcher named Anton Joachimsthaler had not accidentally stumbled across forgotten documents stored in old German railway archives back in the 1980s.

The image above shows a webpage screen capture from amazon.com. Anton Jochimsthaler’s book called “Die Breitspurbahn” chronicles the history of Hitler’s area project to built a new massive-sized super train.

During Hitler’s time, the standard gage of rail for Germany, and pretty much everywhere else for that matter, was the Stephenson Gage, which is 1435mm wide in the metric system and 4 foot 8-1/2 inches in the Imperial English system of measurement. True, the Stevenson Gage of rail was the standard rail type even during the 19th century, and the Stevenson gage was also the standard size for rail lines when Hitler assumed the chancellorship of Germany in 1933, yet after assuming leadership, both Hitler and his advisors quickly saw that the standard gage of rail which was in use at the time was totally inadequate for both industrial purposes and passenger transport objectives.

In the summer of 1936, Hitler commissioned a young and brilliant architect named Albert Speer to design a new pair of rail stations for Berlin: the North Rail Station, and the South Rail Station. Hitler’s plan for a new Berlin also included connecting these two massive and grandiose rail stations with an avenue that would be approximately three miles long and measure 384 feet wide. The thinking behind Hitler and Speer’s plans was to create two new train stations to serve Berlin that would put New York’s Grand Central Station to shame in scale, beauty, and ambition.

It turns out that Hess’s plans for two new Berlin train stations involved erecting buildings that would have been three times the length, three times the width, and three times the height of New York’s Grand Central Station building from that same era. In other words, both Hitler and Speer intended the new and massive Berlin train stations they had envisioned to make a non-verbal social and political statement which would reflect the big ambitions and grans capabilities of Germany’s new 1,000-year Reich that was in the works; thus, while Albert Speer was working on the architectural drawings for a bigger and bolder new set of train stations in Berlin, the idea also arose to build colossal trains that would properly compliment these massive new rail stations.

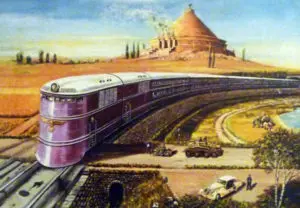

Image courtesy of neverwasmag.com

The image above shows an artist’s mock-up of how a Breitspurbahn train would look as it exists a train station. Image courtesy of yaplakai.com

After assuming the Chancellorship of Germany, Hitler also furthered construction plans for the Autobahn, which was a project to build the best possible road system across all of greater Germany. The plan to build a great new Autobahn road network called for making a road system that would connect all of the cities and regions of Central Europe together by maximizing the capabilities of new automotive technology. Plans for a massive German high-speed road system that would lack intersections and cross traffic was first discussed in the early 1920, but little was done to further this agenda during the years of ineffective Weimar Republic governance.

For example, an early Weimar Republic project from the 1920s called the “HaFraBa” involved building a massive road that would connect Hamburg to Basil, Switzerland by way of Frankfort; however, little was actually done on this project during the Weimar years. Despite the clumsy stupidity of the Weimar government, 1932 actually marked the first time a new Autobahn roadway was completed before Hitler assumed the office of Chancellor; that being said, this first completed stretch of Autobahn only connected a relatively short stretch of land between the western cities of Cologne and Bonn. Despite its relatively short length, this first stretch of the Autobahn was still a success because this road did not have any intersections, animals, bicycles, or pedestrians getting in the way of speeding cars.

Indeed, Hitler’s vision to build the world’s best road system for civilian and military purposes did become a reality, and as of 1936, 136,000 workers were adding new sections to the German highway systems and 270,000 workers were also involved in supporting roles on roadway improvement projects. Hitler and his insiders also envisioned plans for building super-sized tanks and supersized aircraft along with plans for super-sized civil construction projects like the Autobahn network, so whatever project Hitler and his cohorts envisioned and started was going to be bigger, bolder, spicier, and more pioneering than anything that had ever been dreamed of in the past.

Critics have said that every project envisioned by Hitler happened without consideration for cost or practicality, but in defense of Hitler, he did have vision, and he did make plenty of things happened that were firsts. Critics of Hitler’s Breitspurbahn project mostly suggested that it would be cheaper to simply build quadruple-tracked rail lines consisting of two conventional and standard-sized railroad tracks that would go in each direction.

The image above shows a quad railway in England. Image courtesy of wikipedia.org

In October of 1941, Hitler commissioned Fritz Todt, who was the Reich’s go-to man concerning massive building projects, to begin working on the project of building a new and gigantic “Breitspurbahn” rail line network. The German-language term “Breitspurbahn” translates to the words “Imperial Gauge Railway” in English. Both Hitler and Todt saw a need to begin working on the Breitspurbahn project because they each had a strong desire to make the best possible use of any present and future resources acquired from the Reich’s recent occupation of the Ukraine.

For example, initial projections of the 3-meter-wide Breitspurbahn rail lines forecast that an entire seasonal wheat harvest from all of the Ukraine could be transported, distributed, and stored across every other part of Europe in less than two weeks when a Breitspurbahn network was operational. The calculations for the Breitspurbahn project also forecast that once these massive rail lines were in place, then a practically unlimited amount of oil, coal, and metal ores could be moved from the mining regions of Central Asia, Siberia, the Ukraine, and Russia into the industrial regions of Germany and Western Europe, and this massive movement of materials could be done with blinding speed and a shockingly low price-tag to boot.

The Breitspurbahn was essentially Hitler’s plan to build a land-based mode of transportation that would render shipping over the ocean unnecessary. Both Hitler and his inner circle had envisioned their new 1,000-year German Reich to primarily be an empire that was focused on controlling expansive reaches of continental land as opposed to controlling the oceans, so the Breitspurbahn network was intended to serve as the backbone of an entirely a new world order.

Image courtesy of pictolic.com

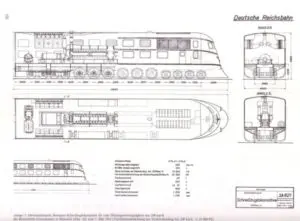

In early 1942, Hitler and Todt actually began working on plans for a future Breitspurbahn rail line, and by November of 1942 Gunther Weims of the Reichsverkehrsministerium’s Ministerialrat in Vienna formally submitted technical specifications and blueprints that were developed in order to outline the actual workings of the Reich’s planned mega-trains. After November of 1943, around 240 engineers, sketch artists, drafters, and other technical professionals were sent to Munich to formally begin working on the Breitspurbahn project. The lineup of technical professionals who were assigned to the Breitspurbahn project included people affiliated with governmental agencies as well as people who worked for a list of power-hitting German industrial corporations. In the end, nothing more than detailed blueprints and artistic concept sketches for the Breitspurbahn network were ever produced; however, some surveying work for future Breitspurbahn rail lines was completed before the end of World War II.

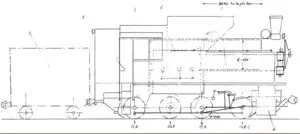

As listed on Wikipedia, the designs for comparatively smaller 3-meter rail lines, as opposed to the initial idea for a 4-meter wide set of railroad tracks, forecasted having standardized train cars that were 42 meters/138 feet in length, 6 meters/19.8 feet in width, and 7 meters/23 feet in height. Each of these standardized 42-meter-long rail cars would also have eight rolling sets of wheeled axels and the passenger cars on these trains would all have two levels. The projected speeds of these Breitspurbahn trains were 65 miles per hour for freight trains and 120 miles per hour for passenger trains.

During 1943, 41 different plans were submitted for Breitspurbahn locomotives, and these designs called for as few as 12 separate wheel axels per locomotive to as many as 52. The horsepower ratings for Breitspurbahn locomotives also varied from 15,300 to 27,500; which are kilowatt ratings ranging from 11,400 to 18,400. The smallest proposed Breitspurbahn locomotive design had a length of only 29 meters/95 feet and the largest design had a length of 129 meters/423 feet. To put things in perspective concerning the proposed massive size of a Breitspurbahn trains, most contemporary diesel-electric locomotives only produce around 2,200 Kw of energy, so the largest of Breitspurbahn locomotives would have produced around eight times the horsepower of a conventional diesel-electric train of today.

Designs for the drive trains of Breitspurbahn locomotives included detailed plans that called for using classic steam locomotive drives as well as electric and hydraulic power delivery systems that would all serve to turn the wheels of these mammoth locomotives. The main power plants for these proposed mammoth locomotives included plans for harnessing the energy contained in classic steam boilers that would potentially burn diesel fuel, coal, or natural gas. Other plans for Breitspurbahn locomotives called for powering these massive rigs with gas turbine engines that would run on different grades of natural gas as well as locomotives that were powered by huge ship-sized diesel engines.

The image above is a schematic of a Breitspurbahn locomotive. Image courtesy of weaponsandwarfare.com

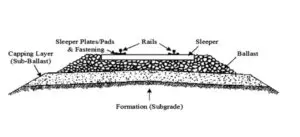

Plans for the Breitspurbahn also called for having rail lines built that were ballastless as opposed to using standard rail lines. The term “Ballastless” denotes rail lines that do not rest on beds of gravel, but instead rest on deep cement foundations, and for the record, “ballast” is the rail industry’s term for the multi-layered gravel beds that support standard train tracks. Ballastless railroad tracks also do not have wooden railroad ties or “Sleepers” as they are known by train industry insiders.

The image above show conventional “Ballasted” rail lines with a gravel bed and wooden cross ties holding the steel tracks in place. Such tracks would not be able to hold a Breitspurbahn train’s incredible weight. Image courtesy of wcti12.com

The image above shows a diagram of conventional “Ballasted” railroad tracks.

The incredible size and weight of Breitspurbahn trains would most likely make using anything other than ballastless or “Slab” tracks impossible because a bed of gravel would be likely to shift under the enormous weight of these huge trains, and the huge weight of Breitspurbahn trains would also be likely to break or damage wooden railroad ties, so there would undoubtedly be a much higher building cost for Breitspurbahn tracks. However, on the bright side, ballastless rail lines may cost a lot more to build, but they have a much lower maintenance cost once they have been installed, plus the total life expectancy of ballastless rail lines is also much longer than that of conventional rail lines once they are built. Therefore, after the rail lines for a Breitspurbahn train system have been built, they will serve for decades while requiring a very minimal amount of maintenance.

The image above shows a basic set of “Ballastless” rails with a deep cement foundation. Image courtesy of railjoadrails.com

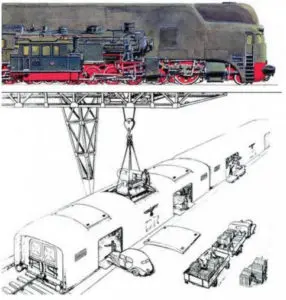

As for the freight carrying capacity of Breitspurbahn trains, each cargo rail car was slated to hold 16 standardized German shipping containers that were approximately 20 feet in length. The designs for Breitspurbahn freight cars also called for roof hatches that would permit standardized shipping containers to be lifted out of these rail cars by crane. It is additionally worthy of note that the German company called Schenker was the first organization to develop and use standardized railway shipping containers, and Shenker used these standardized shipping containers to move cargo on German rail lines as early as 1931. More updated versions of these old “Shenker Containers” have become standardized on a world level since 1931, and modern versions of Shenker Containers are in use pretty much everywhere today. It is also interesting to note that the Shenker company is still in business to this day and this outfit is a successful and publicly traded corporation with a worldwide scope of operations.

Image above courtesy of practicalmachinist.com

As found on Wikipedia, the proposed length of a Breitspurbahn passenger train was slated to be 500 meters/1640 feet with a passenger count varying between 2,000 to 4,000. By contrast, Popular Mechanics magazine has noted that as of 2010, the average American freight train was about 6500 feet/1.2 miles long with 70 standard train cars in tow and a weight of around 15,000 tons. Rueters.com has also noted that as of 2017, the average freight train run by the CSX corporation in America was 1.5 miles/7920 feet long and carried around 178 cars. The Guinness Book of World Records has also declared that the official longest freight train to ever to have rolled was an Australian ore-hauler that was an astonishing 23,000 feet/4.5 miles in length, had 682 cars in tow, and weighed in at 99,732 tons. This record-breaking Australian train traveled 10 hours across Northwestern Australia from the Newman mines to a nearby ocean port back in 2001.

Admittedly, it is hard to know what the average length of a multi-locomotive Breitspurbahn freight train would have been if this system had ever actually been built and put into active service, and it is especially hard to guess what the average length of a Breitspurbahn train would have been over a period of decades. None the less, a good guess would put the length of a standard Breitspurbahn freight train of the 21st century to be about the same length as a standard American or European freight train, except a Breitspurbahn train would have double the width, about one third the number of cars, and around twice the shipping container carrying capacity for the same length.

Part 2. Would Building a Breitspurbahn Network Today Make Sense?

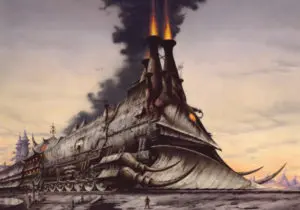

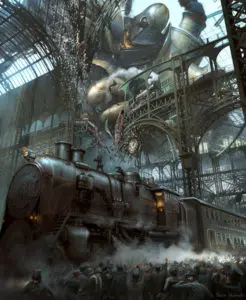

When pondering the question as to whether building a new Breitspurbahn network in the 21st century would make sense or not, the first question to ask is this: How large should a train be? It is important to remember that after Hitler and company discussed the idea of building a mega train that would run on tracks which were more than nine feet wide, many other groups of people proposed building trains that would be even larger in the years that followed. For instance, some plans have been drawn up for trains that would run on tracks which are 29 feet wide! It is also worth mentioning that many fantasy art paintings have been made which envision trains that are the size of moving cities which would be capable of housing hundreds of thousands of people. Science fiction novels have also been written that envision trains which are the size of large cities, and these monstrous city-sized trains move across entire continents on colossal rail networks. Even back in 1942, Hitler and company proposed building a train network that would run on tracks that were 4 meters/12 feet wide, so the concept of building a truly huge train has been around for a while; therefore, we should ask ourselves, how large should a train be?

The image above is a copy of the painting called Heavy Metal Heroes by the artist Rodney Mathews. Image courtesy of rodneymathewsstudios.com

The art print featured above was created by Stephen Martiniere and featured on the website geeknative.com

The image above was created by the artist Ben Wooten and sourced from Pinterest.com

The image above is named Titanomachy-Fall of Hyperion by the artist Marcin Jakubowski. Image courtesy of artstation.com

The image above is the painting called “Dark Future Train” by the artist Marcin Jakubowski. Image courtesy of iamag.co

The image above was created by artist Ying Jie and featured on artstation.com

The image posted above is a copy of Jordan Grimmer’s painting called Rail City. Image courtesy of pinterest.com

The image above is offered by GorosArt on deviantart.com

The image above is a painting by Armand Serrano called “Really Big Train”. Image courtesy of image.co

Image courtesy of pinterest.com

Image courtesy of pinterest.com

It seems that the size of a train is fundamentally arbitrary, yet increasing the size of a train inevitably lowers the cost of transportation on a kilogram-by-kilogram basis due to economy of scale factors kicking in; for instance, trains that run on tracks which are 10 meters across would basically have a carrying capacity rivaling even the largest of ships, so this theoretical 30-meter-wide train track network would inevitably make a mockery of any type of cargo transportation networks that do not cross oceans, yet there must be some practical limit on the size of trains. Thus, if the size of a mega-train is really downright arbitrary, then why not simply elect to use tracks which are only three meters/nine-feet wide?

In 1979, a television show called “Super Train” ran for 9 episodes before it was pulled from the televisions lineup due to low ratings. The premise of this television show was a “Super Train” that was powered by a nuclear reactor which maintained a cruising speed of 190 miles per hour and stocked such amenities as a swimming pool and restaurant. The idea was for Supertrain to be essentially a clone of the television show called “The Love Boat,” except instead of this show taking place on a cruise ship all of the actions in each episode happened aboard a big nuclear-powered train.

No discussion about science fiction super trains would be complete without at least mentioning the novel and movie called “Snow Piercer.” The premise of Snow Piercer is a situation that arises where an experiment to cool the Earth because of global warming problems works far too well and the Earth then becomes a frozen ice ball. In the Snow Piercer story, the survivors of this man-made climate disaster are forced to crowd together on a large train called the “Snow Piercer.” In the Snow Piercer tale, a super-sized train makes an endless loop across a frozen contentment year after year and decade after decade and serves as a small ecosystem for its beleaguered passengers.

Rotten Political Issues

In its original conception, building a Breitspurbahn network was imagined as a massive state-funded project that would require hundreds of thousands of workers toiling over a period of years and perhaps even decades, so this project was not envisioned as something that people would do on a community level, nor even on a nation state level for that matter; but instead, building a Breitspurbahn network was intended to be the work of vast empires or coalitions of nation states. Hitler and his associates imagined that Breitspurbahn rail lines would eventually connect Paris to Vladivostok and also connect central Europe to Southern India. In Hitler’s mind, the final vision for a Breitspurbahn network would involve building railroad networks that would inter-connect Singapore, China, India, and Vietnam, while also connecting China to Central Asia and Europe. The final vision for a Breitspurbahn network also encompassed connecting all of the Middle East including North Africa with Cape Town, South Africa, then the next phase would involve proceeding to connect a pan-African and pan-Middle Eastern Breitspurbahn rail network with the Eurasian rail network somewhere in Jordan or Syria.

Indeed, Hitler made plans to build a massive rail network that would encompass all of Africa, all of the Middle East, all of Central Asia, the entire Indian Subcontinent, all of Southeast Asia, all of China and Korea, plus Russia and the entirety of Europe. The final ambitions for Hitler’s Breitspurbahn rail network were daunting in scope to say the least; however, his initial plans only called for connecting parts of Central and Eastern Europe.

The map above shows an archival document that showcases planned European routes for the Breitspurbahn train network. Image courtesy of i2.wp.com

One problem with implementing Hitler’s idea was the fact that only a limited number of nations or empires have ever had the needed stuff to get something like a continent-spanning Breitspurbahn network built, and at least in the 20th century, the list of nations and empires that were capable of building a train network of the Breitspurbahn’s intended scope was limited to the old Soviet Union, the Zio-American Empire, perhaps the nation of Australia, and of course, the German 3rd Reich. The nations of China, India, and Brazil may have seemed like contenders for building something like a Breitspurbahn network during the 20th century, but until the 1990s, or even later for that matter, none of these decidedly non-European empires would have possessed the technical, organizational, or financial capabilities that are needed to build a continent-spanning Breitspurbahn network.

The unfortunate demise of Hitler’s 3rd Reich was tragic on many levels, but the Reich’s downfall prevented any proper and expansive Breitspurbahn networks from ever being built. As for getting a Breitspurbahn network built in the 21st century, it seems that the Chinese Empire and the Hindu Empire of India are now at least capable of building something like a Breitspurbahn network, yet the Zio-American Empire is now in a state of accelerated decay and collapse, so this dying empire is no longer capable of even maintaining its existing infrastructure; therefore, completing an ambitious project such as building a new continent-spanning Breitspurbahn network is definitely out.

Although the Chinese Empire of the early 21st century seems to have the money, the labor pool, and the technical capability that is necessary to build a new and vast Breitspurbahn network, this empire that masquerades as a nation state is actually plagued by internal instability and is forced to contend with critical internal troubles of all kinds; thus, the unified empire of China that exits in 2021 will probably will not survive as a coherent political entity for too much longer. As for the portions of Europe that rest outside of Russia, this area is presently in an accelerated state of decay which is comparable to that of the imploding Zio-American empire, so large and functioning central governments will disappear for several decades across Europe and the rest of the world in the years to come; therefore, no large and encompassing Breitspurbahn network will be built across Europe or the Americas in the near future. As for India, it is not clear if this huge and hyper-diverse political conglomeration that is commonly referred to as “India” will be able to remain as a coherent political entity for much longer due to massive internal pressures caused by rampant overpopulation, severe environmental degradation, and increased racial, religious, and political conflict.

Perhaps a Use for the Breitspurbahn Can Still be Found

True, building a massive continent-spanning Breitspurbahn network may seem like an impossibility in the 21st century due to the increasing breakdown of large political entities, yet the prospect of building regional networks of Breitspurbahn-sized diesel-electric and steam-powered trains that run on 3-meter-wide tracks is still worth considering. Building shorter lines of Breitspurbahn train tracks is actually not a bad idea when considering the fact that even building these massive train tracks is is still less expensive than building contemporary interstate highways, plus maintaining even very large railroad tracks is also a lot less expensive than maintaining massive highway networks. When an empire has crumbled and fallen to a low level, then broken into pieces, as the Zio-American Empire soon will, this state of affairs ushers in a situation where building at least one regional Breitspurbahn network would offer a cheaper alternative to maintaining a massive government-funded network of costly cement roads.

New nation states that arise after the collapse of dying empires may also find that obtaining sufficient amounts of petroleum to run huge numbers of automobiles is not a viable possibility, nor does it seem likely that the money would exist to purchase and maintain large numbers of new automobiles in a post-collapse world. It is also important to remember that during World War II, many nations in Europe resorted to running cars, busses, and even motorcycles on gasified wood because it was downright impossible to obtain any petroleum during those chaotic times. Two separate articles that were posted on the website lowtechmagazine.com each discussed running cars with wood chips and bio-gas, and it turns out that many European nations, and Japan as well, powered cars, busses, and motorcycles with both methane gas and wood chips during the years of World War II. Bio-gas was burned along with wood products to power busses and other vehicles in many locations during World War II, and this happened because crippling shortages of petroleum forced people to find other sources of energy.

The point to remember is that when empires fail, the vast, complex, and interconnected industrial support networks that people have taken for granted for so long will likely be gone, so people will once again have to leverage local resources to meet their transportation needs, and steam trains that run on biologically based fuels will present an attractive option in this arena. Consider this, when a person purchases a gallon of diesel fuel at a local service staton, they are just buying the end product that a multi-trillion-dollar support structure has procured for them at that moment.

The image above shows a rather typical offshore drilling rig. Equipment like that pictured above are in use by the thousands around the world, so the total investment in the oil industry is truly huge. Image courtesy of issn.com

The image above shows an oil refinery in Iraq. There are presently thousands of huge oil refineries around the world which reflect untold trillions of dollars in global investment in these facilities. For those of you who are not familiar with petroleum-based energy technology, oil refineries process crude oil into lighter refined mixtures such as conventional pump gas that is sold in service stations along with stove oil and aviation fuel. Image courtesy of time.com

When the term “multi-trillion-dollar” is used to describe the infrastructure associated with the petroleum industry, this is the literal truth because the petroleum that eventually becomes a gallon of diesel fuel has to first be found under the ground in the form of crude oil deposits, and the process of finding hidden crude oil reservoirs is actually an expensive and complex undertaking that requires a lot of expensive and sophisticated equipment. Next, these identified crude oil deposits must be extracted from deep under the ground by using very advanced technology, then this recently extracted crude oil needs to be transported to a refinery, after that, this newly-arrived crude oil must be refined into the needed petrol-fuels. Lastly, this refined petroleum-based fuel that comes out of these multi-million-dollar (perhaps billion) dollar refinery facilities must be distributed to retail locations, so the total investment in the infrastructure that produces refined petroleum-based fuels easy stacks into the trillions of dollars. Indeed, the capital outlay needed to produce a gallon of diesel fuel is huge, even for oil that is produced independently at the regional level, so it should come as no surprise if fuel oil shortages arise after large governments fall apart.

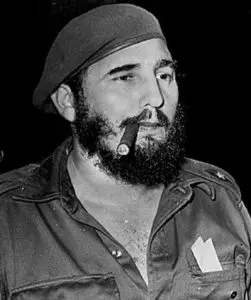

An example of a nation having to make due with its own resources was the island country of Cuba during the years that immediately following the collapse of the Soviet Union in 1991, along with the years of tight international trade embargo that followed this collapse. During the tightest years of Cuba’s embargo, there were shortages of food, but there were also crippling shortages of fuel needed to run cars and tractors, so people had to use bicycles as their chief mode of transportation during this time, and many tractors sat idle on farms. During the toughest years of embargo, the Cubans had to grow small gardens just to feed themselves and the shortage of petroleum also segued into shortages of petroleum-based fertilizer, so food supplies grew even tighter during those years when petroleum-based commercial fertilizers became scarce, plus Cubans had to limit their travel as well during those years. Therefore, during the tight years of embargo, Cuba would have been wise to build a fleet of steam trains that were powered by wood and agricultural waste products such as pressed sugarcane stocks.

It is also worth mentioning that the Cubans could not get any new cars imported into their country during the embargo years, nor could they simply order spare parts for the old cars that were still in service, so they were forced to invent ways to keep old cars on the road by whatever means were at their disposal. The point to remember is that in the event of a system-wide failure, the ability to obtain petroleum-based fuels for cars, busses, and tractors will be severely compromised, plus the ability to source spare parts for cars, and other equipment such as tractors and well pumps will also be compromised. Some of the crucial parts that cars will need to keep running include break pads and tires to name just a few items, so a shortage of replacement parts for all vehicles and internal combustion engines in general will greatly compromise any community’s ability to keep any type of internal-combustion-powered vehicles on the road or types of internal combustion engines at all running.

Image of Fidel Castro courtesy of Amazon.com

If Cuba had built a Breitspurbahn-sized rail line that ran along the entire 777-mile East-to-West length of the island, then this network could have offered millions of people a cheap shipping and transportation network that would have greatly improved this island’s isolated economy and truly boosted the quality of life for all of the island’s inhabitants.

The image above is a map of Cuba that comes courtesy of nationsonline.org

If a shortage of petroleum is an issue for a post-collapse regional government in the coming years, then it would make sense to build a large Breitspurbahn-based train networks that is earmarked for regional travel and regional cargo transportation options, then it would make the most sense to power these large trains with coal if this fuel source is available. Although coal has a bad image for being dirty and polluting, this fuel is still the cheapest energy option available in most places, so running trains on coal offers the cheapest powering option for a train network. If coal is not easily available in a given place, then a train network can run on locally sourced bio-fuels such as wood products, agricultural waste products like the remnants of spent pineapple plants, or fuels that are derived from the biomass of fast-growing plants such as Switchgrass.

Indeed, the initial cost of a Breitspurbahn-sized network of large steam trains would be a bit high at the beginning due to the increased size of these trains and the bigger balastless rail lines that are needed for these networks; however, the maintenance and operating cost of such systems would be much lower than those associated with the upkeep of a present-day federal highway system or more numerous fleets of standard-sized trains.

Think of it this way, it would require less fuel to power one large train than it would to power two medium-sized trains, plus the labor costs and equipment maintenance expenses associated with the upkeep of one larger train would be much less than the price of maintaining two standard-sized trains. The economy-of-scale-derived cost savings associated with a Breitspurbahn network would also become quite telling when large numbers of trains are in service; for example, it would be much cheaper to maintain a fleet of 10 larger Breitspurbahn trains than it would be to maintain a fleet of 20 standard-sized trains.

Ok, So Why Use Steam Trains?

Concerning the topic of building steam trains in the 21st century, it is important to remember that in the 1970s, the African nation of Rhodesia was hit with crippling international sanctions to an even worse degree than Cuba ever has been; therefore, they resorted to using steam trains as a cheap method to move cargo and passengers around their nation. Rhodesia built seemingly old and clunky steam trains once more, even as late as the 1970s, because they knew that they could design, build, operate, service, and repair these pieces of officially antiquated technology without needing foreign support of any kind.

So, just like Rhodesia did back in the 1970s, small post-collapse regional nation states of the future could build large steam trains from their own resources, then operate these chugging behemoths locally and provide a cheaper alternative to the practice of constantly repairing a costly federal highway system. For example, the website urban.org says that in 2018, 187 billion dollars were spent on road maintenance by the American federal government, state governments, and municipal governments combined across the United States, so there is a huge annual budget that is dedicated just to road maintenance on a year-t0-year basis in the Zio-American Empire. However, this huge annual road maintenance budget paid by the Zio-American Empire will probably not be available too much longer if present political trends continue. The state of California’s official website also mentions that around 20 billion dollars are spent on road maintenance across the state each year.

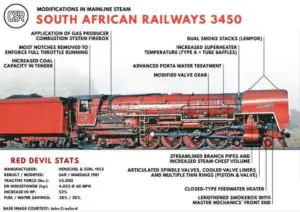

Indeed, steam trains fell out of favor with nationalized rail networks and big corporate rail networks alike in the 1930s and 1940s, but by the 1950s, improvements in steam train technology had once again made this older technology competitive with the newer diesel-electric trains. The problem with the improved steam train designs of the 1950s was that by the time these updated steam trains arrived on the scene there had already been a change of paradigm and the official consensus within national rail network board rooms and corporate board rooms alike was that steam was gone for good. At this time, there is a push to build large fleets of modernized and improved steam trains, and this movement to bring steam trains back into service is not just a load of mawkish pipe dreams, but instead, plans to reintroduce steam trains are a vision that is grounded in math and solid thinking.

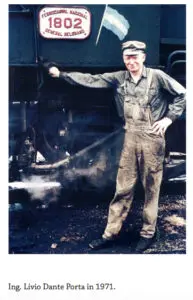

The video above shows South Africa’s “Red Devil” train which was a next-generation steam train that was rebuilt and re-designed by the legendary steam train engineer Dante Livio Porta in 1981. In the 1970s and 1980s South Africa created a fleet of modernized steam trains that were originally built in the 1950s as a counter reaction to perceived oil shortages, and these trains stayed in service well into the 1990s. Indeed, the best steam trains of the 1950s marked a huge leap forward in steam train technology; however, leveraging the best technology of the 2020s offers the possibility of creating even more efficient and capable steam trains.

Image of the “Red Devil” train courtesy of rmweb.co.uk

In the event that large governments dissolve, then building steam trains is a good idea because steam trains are easy to build compared to diesel and electrical trains, and steam trains are less technically demanding to repair and service compared to diesel and purely electrical trains. Think of it this way, steam trains can be manufactured and maintained even with a fairly low-level, crude, decentralized, and antiquated industrial base, so improved steam train technology of the 21st century should be viewed as an attractive infrastructure option for third-world nations that still lack modern infrastructure and are also troubled by having low-IQ populations.

A present-day push to build fleets of steam trains makes sense for third-world nations because they still have poor and antiquated infrastructure, even if no big collapse of empires has happened as of yet. Yes, even very poor nations such as Guatemala which have a national IQ that is below 85 and still continue to lack any “modern” and sophisticated infrastructure would still be capable of building, operating, servicing, and repairing steam trains. As for the prospect of using steam trains in more developed places with high-IQ populations such as China or Europe, reintroducing steam trains in these places would be a great plan after a period of collapse.

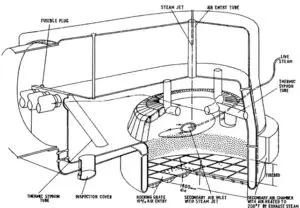

Low Maintenance Steam Trains

It is also worth mentioning that modernized steam trains actually offer their operators not only lower fuel costs, but also much lower maintenance costs. In the past, the high cost of maintenance for steam trains mostly stemmed from a constant need to clean the soot deposits from the fire tubes and the smoke boxes; however, new and improved firebox designs created by the great Argentinian steam train visionary Livio Dante Porta virtually eliminate the need for cleaning the soot out of a steam train’s fire tubes and smoke box, plus water treatment regimens invented by Porta virtually eliminate scale buildup within boilers. Preventing any mineral scale formation from ever forming on the insides of steam train boilers is important because the presence of mineral scale inside boilers greatly reduces operational efficiency and the process of removing these scales has traditionally been costly, slow, and laborious.

Porta’s water treatment method that eliminates scale buildup within boilers greatly boosts steam-making efficiency because having scale buildup on the walls of boilers creates a barrier which inhibits the movement of heat from the fire box’s combustion to the boiler’s water. Additionally, Porta’s unique water treatment regimen deliberately creates a layer of foam on the top of the boiler’s water surface, and this layer of foam captures particles that are suspended within the boiler water, which in turn prevents water-borne particles from ever entering the working steam system in the first place. Porta’s same water treatment regimen that prevents small water-borne particles from ever entering working steam lines also practically eliminates wear on the steam cylinders and the steam piping system itself, and this elimination of wear on working steam equipment happens by eliminating friction from moving abrasive micro-particles. Not having any abrasive micro-particles in the steam lines makes trains that use the Porta water treatment regimen virtually maintenance free for years on end.

Porta’s revolutionary boiler water treatment regimen reduces scale buildup within the boiler to such a high degree that only one internal pressure washing per year is necessary for boiler maintenance, and these “hot wash” boiler cleanings only take around 5 hours. A “hot wash” boiler treatment involves pressure washing the scale off of a train’s fire tubes and boiler walls while the boiler is holding water that is just below the billing point. A “hot wash” is the way to go when removing mineral scale from the insides of boilers because the boiler water never has to be drained and nobody has to crawl into the boiler and manually scrub the scale off of the equipment, so this process is a lot faster, cheaper, and less labor intensive. Lastly, new and improved graphite steam piston rings and cylinder sleeves greatly extends the life of a train’s powering system and greatly reduces the need for routine maintenance.

The Sentimental Factor

It is worth mentioning at some point that steam trains are also well liked by the public for sentimental reasons, so there is something nice about riding a steam train as a passenger. It is worth discussing the practical merits of running steam trains that can burn cheap bio-fuels or can run on very cheap types of coal; however, steam trains can also be viewed as cool cultural artifacts that also happen to serve a practical purpose. Despite their seeming practical advantages, diesel powered trains have never captured the public’s hearts or the public’s imagination, so operating fleets of steam trains offers a sentimental value that transcends simple matters of economics.

A 2018 article published in The Guardian authored by Simon Jenkins mentions that Britain now hosts 120 heritage and local rail lines, and many of them run on steam trains. Admittedly, these heritage steam train lines in Britain mostly serve a leisure and tourism market, yet Jenkins estimates that passengers will pay up to twice the cost of a regular train ticket to ride on a steam train; thus, the crux of Jenkins article is that reintroducing steam trains to Britain’s National Rail Service just might boost ridership and increase profitability. Even outside of Britain, heritage steam train lines that cater to tourists and leisure travelers are a thriving business and one with a high growth potential, so building fleets of passenger trains that run on steam power actually looks like a winning idea from a purely financial perspective.

The image above shows a photo of the Durango & Silverton Narrow Gauge Railway line that runs near the town of Durango, Colorado. The Durango and Silverton heritage steam train line is a very popular and profitable tourist attraction, which attests to the public’s ongoing love for steam trains. Image courtesy of durangotrain.com

The image above shows a small gauge steam train running at the Cass Scenic Railroad state park in Cass, West Virginia. Image courtesy of steamengineresource.weebly.com

Part 3. Powering Options for Steam Trains

The newest and most improved steam train designs also offer better reliability and better fuel economy than contemporary diesel-electric trains, plus steam trains can run on a variety of combustible fuels such as coal, natural gas, all manners of biofuels, diesel oil, and unrefined crude oil which is also called “Bunker.” So, in other words, steam trains are not fussy about the types of fuels that they burn.

Burning the Coal

Coal has acquired a bad reputation for being a very dirty and polluting energy source that is essentially past its time and needs to be phased out as soon as possible. True, coal has acquired its bad reputation for good reasons; indeed, coal releases a lot of particles when it burns and coal also releases traces of poisonous heavy metals such as cadmium and mercury into the atmosphere when it is combusted. The toxic substances that are released into the atmosphere when coal is burned also eventually work their way into many areas of the ecosystem such as streams, lakes, and ground water when coal-polluted rain falls. Coal often contains many poisonous chemicals such as lead and arsenic because coal is a mineral that is mined, so there are bound to be traces of all sorts of elements within the deposits of this mineral. Worse yet, coal that is mined at many deposits naturally contains traces of radioactive elements such as uranium and thorium, so when this type of radioactive coal is burned, the radioactive elements in the material eventually work their way into the ecosystem and this causes problems; whereas, these elements would rest safely under the ground if this coal was never mined and then burned.

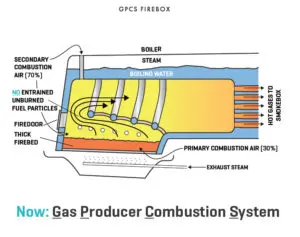

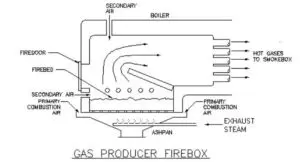

The act of extracting coal from the ground is also looked upon unfavorably by society these days, and for good reason. Indeed, coal is often mined in vast open pits that scar the landscape, eliminate streams, compromise the ground water, and destroy animal habitats. Coal mining is also associated with lung problems for the workers in this field (and their family members for that matter), so it comes as no surprise that the coal industry still has a bad public image. Yet, despite its faults, burning coal for energy will remain an item for the foreseeable future because coal combustion offers a cheap way to create heat, and the heat made by burning coal can then be used for warming buildings, cooking, making electricity, and of course, powering trains. At this time, burning Lignite and Sub-bituminous coal offers the cheapest energy option on the table for powering steam trains despite other fuel options being around. The key to making steam trains that burn coal truly economical to operate is to build a new generation of trains that are powered by Gas Producer Combustion Boxes, or GPCS systems for short.

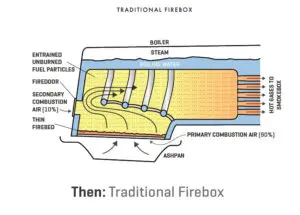

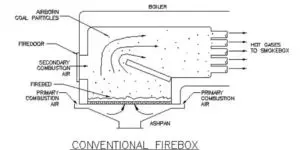

The GPCS system was invented by the great Argentinian train engineer Livio Dante Porta. The GPCS system is a true innovation within the field of steam trains because this firebox design offers train operators a level of combustion efficiency that is far ahead of any previous steam train boiler designs. The GPCS system works by burning the smoke that is produced from the combustion of solid materials, whether these materials be coal of biomass. The long-standing problem with steam train fireboxes is that they tend to be compact, but not very efficient. For example, the combustion systems in power plants do not need to be compact, so they can burn coal with much more restricted inflows of air and power plant boilers can also offer more efficiency by having larger and more dense arrays of boiler tubes that a train would not have the space to host. That being said, having much tighter inflows of air in power plant fireboxes makes for more complete coal combustion; however, having cooler burning temperatures inside of a power plant’s firebox along with longer burning times is the trade-off for having better combustion efficiency.

Essentially, steam trains have historically sacrificed efficiency to deliver power whenever they have burned any type of fuel. The upshot of a steam train’s boiler needing to be as compact and powerful as possible means that up to 50% of the coal that is burned within a conventional train’s firebox simply goes up the chimney as particles, C02, and carbon monoxide. On the other hand, Porta’s GPCS firebox design ensures that the particles in the fuel’s smoke, along with the carbon contained in the C02 and Carbon Monoxide from the fuel combustion, are all burned before they ever reach the train’s chimney.

The basic working principle of a GPCS firebox is a scenario where coal pieces are burned with a restricted airflow of only 30% that of a convention firebox, and steam is added to this reduced airflow in order to ensure less particles enter the fire tubes in the first place. Plus, steam is added to the fireboxes intake air supply to ensure that cooler burning temperatures are also achieved. Within a GPCS firebox, once the smoke from the cooler burning fire moves upward, air inlets that are strategically placed around the upper levels of these types of fireboxes allow air to enter, which creates swirling vortexes where the gas given off by the burning fuel is burned itself. Also, the spinning motion of these burning exhaust gas vortexes acts as a sort of centrifuge that flings many of the solid particles floating in the smoke out towards the walls of the fire box which in turn prevents them from ever entering the train’s fire tubes. According to trainweb.com, trains built with Porta’s GPCS boilers have achieved up to 80% efficiency when running, whereas conventional trains have only topped out at efficiency ratings around 50%.

Steam trains with GPCS fireboxes are a game-changer for steam trains because these types of combustion boxes can reduce coal consumption by around 30%, and GPCS firebox systems also reduce water use by around 30%. Admittedly, a 30% reduction in water and fuel use is good but not what Porta had initially hoped for, so GPCS boilers are a great technology, but they have always been a little bit of a disappointment because they do not deliver the savings that engineers would like to see. It is also well worth mentioning that engineers who are working in our time could improve upon the truly brilliant work done by Livio Dante Porta, so the possibility of achieving fuel and water savings of more than 30% on steam trains that are designed and built in the 21st century is very possible.

A truly efficient steam train of the 21st Century would have a Gas Producer Fire box, would use the Porta Water Treatment system, and would also use Porta’s excellent chimney designs. Other innovations such as improved insulation and improved “Compound” driving mechanisms also offer the possibilities of operating steam trains that have much lower overall operating costs than diesel-electric trains. “Compound” driving systems are arrangements on steam trains where the escaping steam from the driving cylinders is reused to power additional driving cylinders. In the late 1990’s, which was a few years before Porta’s death, Porta designed his own train from the blueprints up, and this train design was named the LVM800 or the “Prometheus Project.” Porta’s LMM800 locomotive concept is worth mentioning here because this brilliant train design represents the best know steam train concept to date, yet no working prototype of this train was ever actually built; however, engineers from our time could easily apply Porta’s ideas and even make a few design improvements.

The above image shows a working diagram of the Compound driving mechanism found on Porta’s Prometheus Project train design from the 1990s. Image courtesy of martynbane.co.uk

The image above is a 1998 rendering of Porta’s Prometheus Project train that was designed specifically to help Cuba’s economy, yet was never built. Image courtesy of martynbane.co.uk

The above image of Porta’s visionary LVM800 steam train design was made in 1998 as a commission by artist Robin Barnes. Image also courtesy of martynbane.co.uk

Despite its disappointments, the boosted efficiency of GPCS firebox designs still opens the door for trains to be powered by low-quality Lignite and Sub-Bitumous coal that traditionally has offered too little energy per kilogram and burned too dirty to work as a power source for trains. A GPCS system also offers the perk of permitting a steam train to meet more stringent environmental regulations while also not releasing ugly plumes of black coal smoke. Yet another perk offered by the GPCS firebox design is cleaner coal ashes; the ashes made by burning coal in a GPCS system are less likely to clog the air intake holes in a train’s combustion box because far fewer glass-like nuggets of “Clinker” will ever form due to this type of firebox having lower combustion temperatures. Indeed, having lower fuel burning temperatures makes for less clinker pieces that tend to clog air intake which reduces operating efficiency.

Additionally, a GPS system burns the particles in coal smoke, so even combusting very dirty and low-quality coal will not leave heavy soot deposits on the boiler’s fire tubes, nor will it leave heavy soot deposits on the train’s superheaters, nor on smoke boxes which are located in the forward areas. An absence of particles released by burning low-quality coal not only eliminates the need for constant servicing, but it also prolongs the life of boiler fire tubes to around 30 years, even under continual operation.

Image of Livio Dante Porta furnished courtesy of the Coalition for Sustainable Rail’s website.

The image above shows the layout for a traditional and inefficient steam train firebox. Image courtesy of the Coalition for Sustainable Rail website.

The illustration above shows the basic layout for a conventional steam train firebox. Image courtesy of trainweb.org

The illustration above outlines the basic design of Porta’s GPCS firebox design. Image courtesy of the Coalition for Sustainable Rail website.

The image above shows a GPCS firebox design. Image courtesy of trainweb.org

The image above shows a “Cyclone” styled Gas Producer Firebox (GPCS) design. The Cyclone Gas Producer design creates a swirling cloud of burning exhaust gas which acts as a centrifuge and flings solid particles out of of the burning gas towards the edges of the firebox. A good Cyclonic GPCS firebox will not only create optimal fuel combustion efficiency, but such a system will also minimize accumulation of soot buildup on the insides of the boiler fire tubes and the train’s smokebox. Image courtesy of martynbane.co.uk

Bio Fuel Powering Options

First, let it be said that Livio Dante Porta’s GPCS firebox systems work very well when burning bio-fuels as well. In fact, bio-fuels produce a fraction of the ash that even the cleanest burning coal produces, so bio-fuels offer a clean and affordable way to power steam trains. The actual numbers indicate that burning bio-fuels leaves anywhere from 25% to 10% of the ash that is left over after coal is burned, and burning bio-fuels greatly reduces the amount of glass-like “Clinker” pieces in the ash which might clog the fireboxes air intakes holes. Another advantage offered by burning bio-fuels is that the ash residue that is left over after burning these types of fuels is completely non-toxic and suitable for fertilizing crops; whereas, the ash that is left over after coal has been burned, which is referred to as “Fly Ash,” is typically loaded with toxic trace minerals and is unsuitable to be used as anything other than an additive to cement.

The best bio-fuel option for powering steam trains seems to be filling fire-boxes with wood chips. Wood chips offer the best bio-fuel option for making electricity or moving trains because wood chips offer the third highest energy density per cubic meter of any known bio-fuel; the most efficient of the solid biofuels is terrified wood briquettes followed by compressed biomass pellets and briquettes, yet wood chips are very cheap and easy to produce compared to other biofuel options.

Indeed, solid chunks of kiln-dried dried wood do have more energy than wood chips on a kilogram-by-kilogram basis; however, larger chunks of wood tend to burn too slowly to provide the kind of energy that is needed to keep a larger train rolling. Wood chips are an attractive option for all kinds of energy applications because they burn very hot, they burn very fast, and they leave very little residue after being burned, so automated fuel feeding mechanisms the stoke combustion chambers with wood chips can be very responsive to fluctuations in energy needs. True, many trains have been powered by burning chord wood and even larger log sections, but trains that run by burning larger wood pieces have to be rather small because the energy that is available when larger wood chunks are burned is much lower than that of burning wood chips or wood pellets. Think of it this way, burning large pieces of wood demands small trains, so big wood means small train.

Early steam trains that ran on split firewood pieces were popular transportation options during the frontier expansion days in the American West as well during the settlement of Australia and the Russian expansion eastward into Siberia. Many rough and simple frontier trains used axe-split firewood as a power source simply because that was the fuel which was most readily available at the time, however, the downside to burning chord wood was a low availability of power that kept these types of trains rather small. Image courtesy of pacificing.com

The image of an old frontier wood-burning train is furnished by texashistory.unt.edu

The highest energy density per kilogram for bio-fuels belongs to Torrified wood products, except the process of producing this refined type of bio-mass fuel is still too costly and dangerous for this energy option to gain true mainstream acceptance. The process of creating Torrified bio-mass fuels involves placing pretty much any type of solid biomass that will burn into a tightly sealed and airtight chamber then heating the materials up to about 300 degrees Celsius/ and evaporating the natural tars and lignans in the biomass. After the tars, oils, and lignans in the biomass have been removed by the gasification process, the remaining biomass is then compressed into briquettes.

The end result of the Torrification process is “Bio Coal” that has a very high energy density and a natural resistance to absorbing moisture, except the problem with producing this nice bio-fuel is the fact that the gummy tars and lignans which are released during the gasification process collect inside the vent piping and necessitate costly routine cleanings. The other big problem with the Torrification process is the fact that the gasses released by heating the bio-mass in a sealed chamber are terribly toxic and very dangerous, even at shockingly low atmospheric concentrations, so the process of making Torrified bio-mass products is actually quite hazardous on top of being costly.

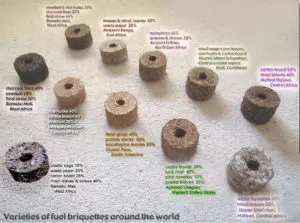

Admittedly, dried wood chips provide the cheapest and most practical bio-fuel solution for powering a steam train; however, there is still a huge amount of agricultural and logging waste products such as sawdust that are in circulation which can also provide a huge about of energy. Turning agricultural waste products into useful biofuels involves making these waste items into briquettes of compressed bio-fuel that are held together with binding agents. For example, briquettes of biofuel can be made from combustible bio-materials such as leaves, rice husks, palm fronds, and wood waste products like the small branches of trees that have been cut down for lumber.

The image above shows the city of Burlington, Vermont’s McNeil power generation station. The McNeil power station burns around 76 tons of wood chips per hour and produces up to 50 megawatts of electricity at peak load. Image courtesy of sevendaysvt.com

The image above shows the Varten Bio-energy plant in central Stockholm, Sweden. The Varten power and heating plant burns around 12.5 thousand cubic meters of wood chips per day at 97% thermal efficiency. The Varten power plant now provides steam-based central heating to around 190,000 households that compromise 60% of Stockholm’s residences, plus thousands of commercial and institutional units are heated by steam from this plant. The Varten plant also produces around 1/3 of the electricity for the city’s 1.5 million residents, and all of this incredible energy is produced just by burning wood chips! Image courtesy of arch daily.com

Nuggets of bio-fuel can be made from pretty much any type of bio-matter that will burn, and the process of making these ingots of combustible bio-material involves pulverizing combustible materials then compressing and bonding these loose substances together with adhesives such plant-based starches or molasses. Plant-based starches that are suitable to use as binding agents for bio-mass briquette production operations can be sourced from such crops as potatoes, wheat, corn, oats, and beats. The needed concentration of starch to bind a workable bio-mass briquette is around 5-7% starch matter within a solution of water.

Yet another drawback to producing biomass fuels is the fact that many agricultural waste products have too much moisture in them to simply burn as an effective fuel; therefore, many types of biomass must be kiln-dried before they can be pulverized and mixed with a binding agent and then finally compressed into useable pieces of fuel. The kilns that dry biomass and prepare this material for compression into pellets or briquettes are powered by their own product, so this process is self-sustaining, yet using some of the final product to make more of itself does add to the cost of biomass briquette production. The main drawback to using compressed biomass briquettes as an energy source is the higher cost than either coal or wood chips; however, biomass briquettes offer the advantage of allowing people to make good use of unwanted waste products.

It seems that the best size to choose for compressed bio-mass pieces that are slated for powering steam trains is ingots that are about the size of hockey pucks or scallops. Nuggets of bio-fuel that are about the size of hockey pucks are the best substitute for coal because they burn with a lot of energy, produce a modest amount of ash, and can be easily loaded into a train’s firebox with a shovel.

The image above shows a pile of waste product from a logging operation. Material such as what is shown above provides a very valuable source of materials that will work suffice for making both wood chips and briquettes of compressed bio-mass that can power electrical generation equipment and steam trains. Image courtesy of ecostan.com

The image above shows how coppiced shoots from Willow trees can be sustainably harvested as a source of bio-fuels on the community level. Image courtesy of gardenissustrated.com

Image of coppiced and pollarded trees furnished courtesy of awaytogarden.com

The image above shows a huge pile of recently harvested coppiced Willow shoots that are slated to become biomass fuel for a steam boiler. Image courtesy of sciencephoto.com

The image above shows a pile of wood chips which were sourced from coppiced Willow trees. The pile of Willow wood chips seen above is awaiting a burn cycle at a regional power plant. Image courtesy of researchgate.net

The image above shows an indoor storage facility for wood chips in the United Kingdom. Wood chips offer a large-scale power option that runs many massive electrical and heating plants around the world. The low-cost and sustainability of wood chip power makes this energy source an attractive option for not only heating buildings and generating electricity but also for powering steam trains. Image courtesy of rubbusa.com

![]()

The image above shows what wood chip boiler fuel looks like up-close. Image courtesy of everypixel.com

The image above shown the different types of agricultural waste products that can be repurposed into briquettes of combustible bi0-mass fuel. Image courtesy of paradisedivingasia.com

Agricultural waste products such as corn stalks, peanut shells, rice husks, cherry pits, and corn cobs can all be pulverized and compressed into bio-mass briquettes. On the other hand, some crops that grow very quickly and require small amounts of water and fertilizer such as “Giant Cane” can be deliberately planted and harvested as a source of raw bio-mass which can be compressed into bio-fuel briquettes. Image courtesy of wikipedia.org

As a pure energy production crop, Switchgrass does not produce biomass quite as prolifically as Giant Cane. On the other hand, this plant is also useful as a source of animal feed and as an erosion control plant, so the versatility of the Switchgrass plant still makes it an attractive energy production crop. Image courtesy of wised.co

The image above shows different types of bio-fuel briquettes. Image courtesy of biodiesel-machine.com

The image above illustrates how nuggets of bio-fuel can be made from an incredible array of bio-matter that will burn. Image courtesy of stoves.bioenergylists.org

The image above shows a bio-mass brick press and the finished product. Image courtesy of biomass-briquette.com

The image above shows how a wide assortment of bio-mass can be transformed into energy-dense briquettes of combustable fuel. Image courtesy of briquette-machine.com

The image above shows different briquettes of bio-mass that are suitable for use as fuel for steam trains. The briquette furthest to the right in this illustration was made by hand from shredded bio-mass that was bound together with vegetable starch, rolled into a ball by hand, and then finally dried in the sun until it was dry enough to burn well. Image courtesy of bioenergylists.org

The image above shows compressed bio-mass briquettes while they are burning. Image courtesy of briquettsolution.com

The image above shows bio-coal sourced from Indonesian coconut husks and shells that is burning during in a laboratory test. Coconut shells and husks are just one of many agricultural waste products that can be harnessed as a source of energy. Image courtesy of brilliantbriquette.rom

Conclusions

The most up-to-date steam train designs not only offer the lowest levels of regular maintenance of any known powering method for trains, but these designs can also meet today’s stringent pollution standards, so the idea of building a new generation of steam trains is not a foolish idea. A full discussion about the specific features of the most modern and up-to-date steam trains as well as a discussion about the most brilliant engineers in the movement to modernize steam engines would be long and intricate, so this talk will be left for another day; however, more information about the specific methods used to build efficient and modern steam trains can be found on the website straction.com and at the website called Coalition for Sustainable Rail.

Lastly, designing a larger version of a steam train that has Breitspurbahn-sized measurements is not simply a matter of taking existing plans for regular-sized steam trains and then scaling them up. No, simply scaling up the designs for regular-sized steam trains will not work when designing Breitspurbahn trains because as structures grow in size, the internal stresses grow exponentially, so any designs for future Breitspurbahn steam trains would need to be designed for larger dimensions from the very beginning. The best thing to do when designing Breitspurbahn trains would be to study and reference the plans originally developed by the 3rd-Reich and then build upon the work done by the Germans back in 1942 and beyond.

The downside to developing a new set of Breitspurbahn plans would be the high development costs that are needed for such a project and the long testing times that would be required to develop good and reliable locomotives, yet once the testing and engineering work is complete, the process of building a new Breitspurbahn network would simply be a matter of following the steps in a proven instruction manual.

K. C Jones, you Better Watch Your Speed!!

Image courtesy of pixie.org